-

MenuBack

-

Plastic Enclosures

-

-

Customisation

-

-

-

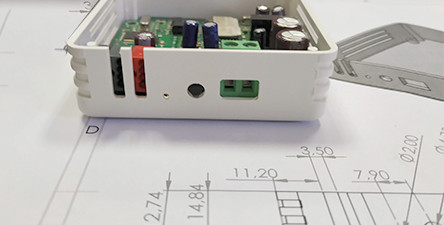

CNC MachiningWe provide custom CNC machining services quickly and reliably for boxes and small plastic or metal components used in electronic assemblies.

Cutouts / drillings to fit electronic circuits, screens, buttons, cable inputs and outputs, threaded holes, recessed surfaces for membrane keyboards, adhesive faceplates, etc. More info

-

-

-

-

-

-

-

-

-

-

-

-

-

Downloads

-

-

Company

-

-

Contact

-

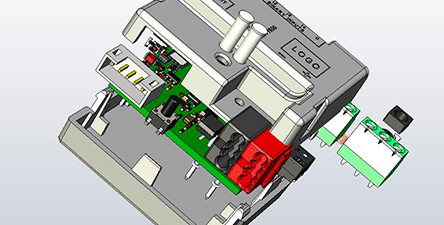

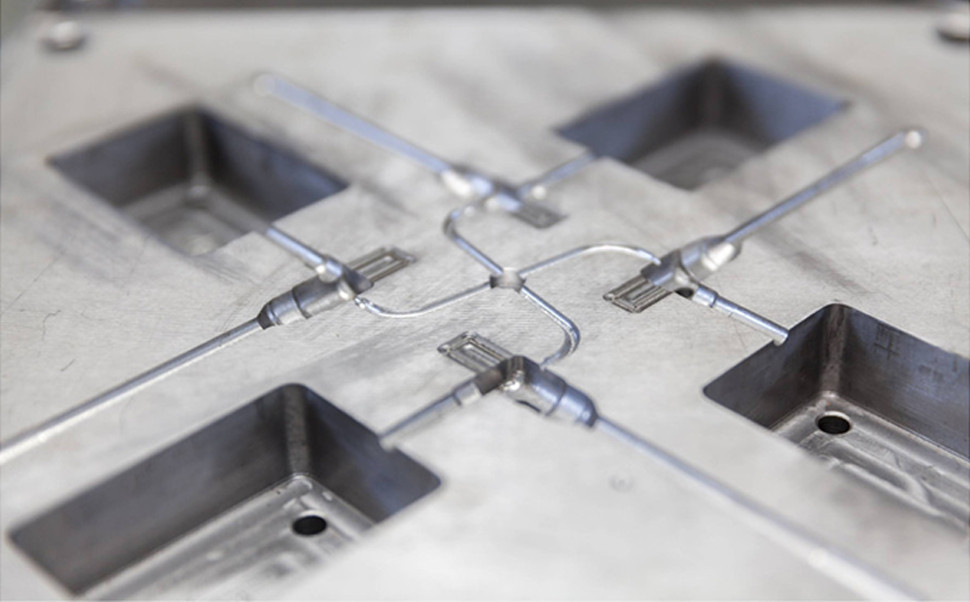

Common challenges in designing and manufacturing injection molds for plastic enclosures

Comparte esta noticia

The manufacturing of plastic injection molds is a critical step in the development of boxes for electronic devices. At Supertronic, with decades of experience in the sector, we have identified the most common challenges faced by our clients during this process. Understanding these issues is essential to avoid them and ensure the success of your project.

1. Inadequate Design for Injection: A common mistake is designing parts that do not take into account the limitations and requirements of the injection process, such as uniform wall thickness to prevent deformations.

2. Material Selection: Incorrect choice of material can affect the durability and functionality of the box, especially under extreme conditions.

3. Improper Placement of Parting Lines: This can lead to aesthetic or functional issues, hence careful planning of the mold is crucial.

4. Inefficient Cooling Channels: Inadequate cooling can result in long cycle times and defects in the molded parts.

5. Underestimation of Material Shrinkage: All plastics shrink when cooled, and not accurately calculating this shrinkage can result in parts that do not meet dimensional specifications.

At Supertronic, we offer technical advice and support at every stage of your project to overcome these challenges. Our goal is to ensure that every injection mold meets the highest standards of quality and functionality.