Experts in tailored plastic enclosure: Design and Manufacturing for Electronic Devices

Comparte esta noticia

In electronic device manufacturing, selecting the right enclosure is a key factor in ensuring the protection, functionality, and design of the product. There are two main approaches: standard enclosures and tailored plastic enclosures. Each option has its advantages and disadvantages, which must be evaluated based on the project’s needs.

At Supertronic, we have over 50 years of experience in designing and manufacturing both types of plastic enclosures. Our goal is to provide optimal solutions for electronic devices, ensuring a perfect combination of quality, innovation, and efficiency.

Additionally, our commitment to excellence is reinforced by our ISO 9001:2015 certification, which guarantees rigorous quality control at every stage of the process—from designing and manufacturing our own molds to plastic injection molding—all within our facilities in Barcelona.

This close relationship with our clients allows us to provide a more direct and personalized service, ensuring thorough project tracking and guaranteeing that each manufactured enclosure meets our high-quality standards.

Tailored Plastic Enclosures: Full Integration of Electronics, Material, Color, and Design

At Supertronic, we take customization to the next level with our exclusive tailored plastic enclosure design and manufacturing service. With over 50 years of experience and more than 300 tailored designs completed, we have developed unmatched expertise in creating plastic enclosures for all types of electronic devices, from portable gadgets to large desktop equipment.

Tailored plastic enclosures require the design and manufacturing of a mold, which allows us to produce exclusive enclosure models for our clients. This ensures seamless integration with their electronic components and offers complete control over the material, color, and design of the enclosure.

✅ Advantages of Tailored Plastic Enclosures

- Exact design: Tailored to the device’s dimensions, materials, and specific needs.

- Branding and differentiation: Allows logos, colors, and unique brand elements to be incorporated.

- Functional optimization: Predefined holes for connectors, ventilation, and internal mounting systems.

- Enhanced user experience: Facilitates assembly and reduces installation errors.

❌ Disadvantages of Tailored Plastic Enclosures

- Higher initial cost: Requires investment in mold design and development.

- Longer production time: Dependent on modeling, prototyping, and manufacturing processes.

- More demanding validation process: Requires testing and adjustments before mass production.

Although tailored plastic enclosures require a more extensive development process, their precision and quality ensure a unique and optimized product for its intended function.

Supertronic's Tailored Plastic Enclosure Manufacturing Process

At Supertronic, we follow a structured methodology that guarantees the highest quality standards in every manufactured enclosure.

1. Design and Prototyping

We work closely with our clients to understand their project and design a 3D model of the enclosure that meets their exact specifications.

- Once the 3D design is approved, a 3D-printed prototype is created.

- This prototype allows for interaction with the design, enabling adjustments and optimizations before mold fabrication.

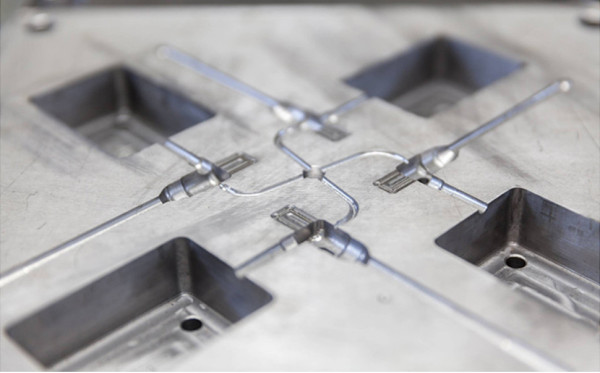

2. Injection Mold Fabrication

- Based on the approved design, we create the technical design of the plastic injection mold, ensuring dimensional precision and optimizing flow and cavity distribution.

- Once the technical design is validated, we manufacture the mold in our facilities, using cutting-edge machinery to achieve the highest quality at competitive prices.

- After mold production, we create initial samples to validate the enclosure and make any necessary adjustments before starting full-scale injection molding.

3. Production and Quality Control

- Once the samples are validated, we proceed with mass production using materials specified by the client (ABS, polycarbonate, polypropylene, etc.).

- We apply ISO 9001:2015-certified quality controls to ensure that every injection-molded enclosure meets our quality standards.

Challenges in Tailored Plastic Enclosure Manufacturing

Injection mold fabrication is a highly technical process that directly impacts the quality, functionality, and durability of tailored plastic enclosures.

An incorrect design, poor material selection, or inadequate planning can lead to structural, aesthetic, or assembly issues in electronic devices. To avoid these problems, a well-optimized design process is essential, where every detail—from wall thickness to partition lines—is carefully calculated.

At Supertronic, we apply a comprehensive approach to ensure that every mold meets the highest quality and precision standards. From the initial design to mass production, we support our clients at every stage of development, ensuring that the selected materials are suitable and that plastic injection molding optimizes both production time and enclosure durability.

Our commitment is to deliver efficient, innovative solutions tailored to the specific needs of each project.